How to handle fuel contamination in jet and diesel fuel

Even small amounts can stop engines working, and microbial forms of contamination can cost thousands or even millions to fix. Luckily, there are a number of ways you can deal with the risks before they get out of hand.

What is microbial fuel contamination?

Fuel contamination is caused by microorganisms that enter fuel from the surrounding atmosphere. Certain species of microorganisms are robust enough to thrive in the fuel, and under the right conditions, they can cause damage to fuel systems, tanks and bunkers.

After leaving the refinery, fuel will almost always have some level of contamination in it. However, fungi such as Hormonconis resinae, bacteria and yeasts will cause the most damage to fuel and the engines that use it.

The different types of fuel contamination

Rust and scale are the principal cause of particulate contamination in fuels. Almost any fuel distribution process or tank will contain some rust. Other particulates include:

- Airborne matter that enters through tank openings or are not caught by the seals of floating roof tanks, e.g. dust and pollen

- Objects incoming through from split hoses and damaged filters, e.g. rubber particles and fibres

- Particulates from microbiological contamination, e.g. biomass and microbial by-products.

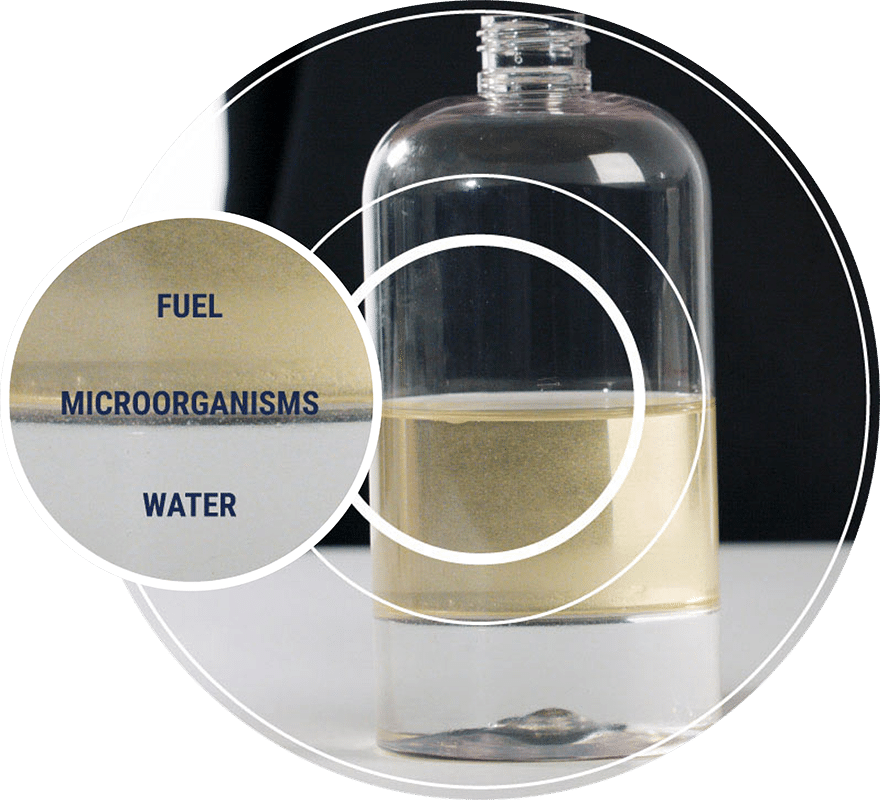

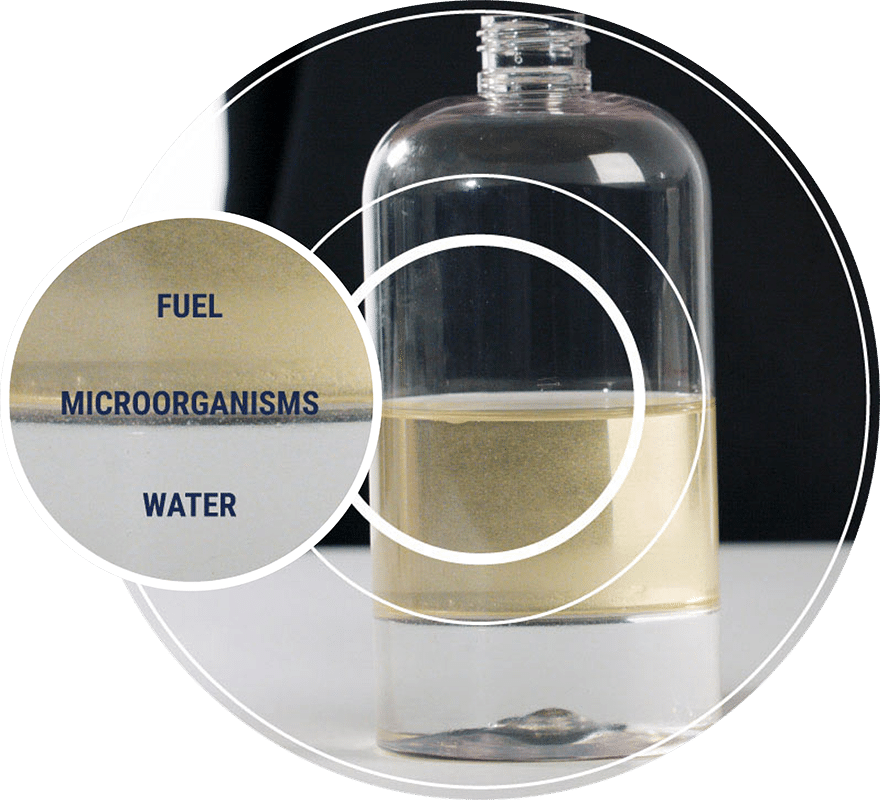

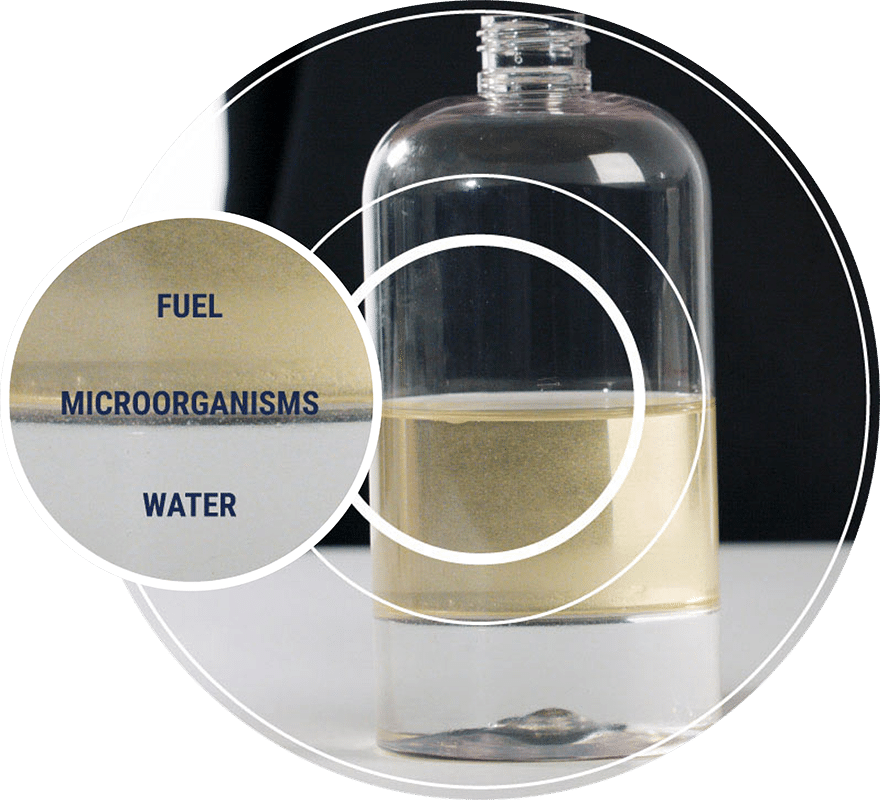

The build-up of water is inevitable with stored fuels or fuels used for propulsion or to provide energy. Even when there is low water content at the start of the fuel supply chain, there are many opportunities during the fuel’s journey where vapour can be absorbed and eventually result in free water. Even the smallest amount of water, a droplet, is sufficient for microbiological growth in some cases.

Other Fuel Types. Consignments of fuel are sometimes tainted with other petroleum products, like gasoline. If this happens to the extent that the resulting mixture falls outside of acceptable standards for the fuel, there is no solution and the fuel itself must be re-despatched to the supplier for salvaging.

One pollutant that could be found in airport fuel supply infrastructures is Fatty Acid Methyl Ester (FAME). FAME is banned from aviation fuel, so even a 0.001% trace of it makes the fuel unusable.

While fuels are sterile after they are initially refined, they usually become contaminated with microbes that are ever-present in air and water. The microbes living in middle distillate fuels include bacteria, yeasts and fungi.

As microorganisms such as the fungi H.res grow, they form a cell-based matter known as biomass. Biomass may clog fuel filters, and microbial cells may produce acidic by-products that cause structural metal corrosion of tanks.

The presence of free water in a fuel system promotes microbiological growth, which usually occurs at the fuel-water interface. Higher atmospheric temperatures accelerate microbial growth.

Microbial Contaminated fuel symptoms

Fuel consumption will increase, and the engine could eventually (or suddenly) stop working.

However, there may be other symptoms; fuel gauges may appear to be inaccurate, and filters become clogged with biomass. In extreme cases, fuel tanks can start to leak.

How do I detect the different fuel contaminants?

Particulates can be detected through simple visual observation of the fuel itself and/or through chemical analysis if the particulate size is beyond visual inspection limits.

Water can be detected through simple tests. Commercially available water tests for fuel show, as an example, whether the water in fuel is above or below 30 parts per million.

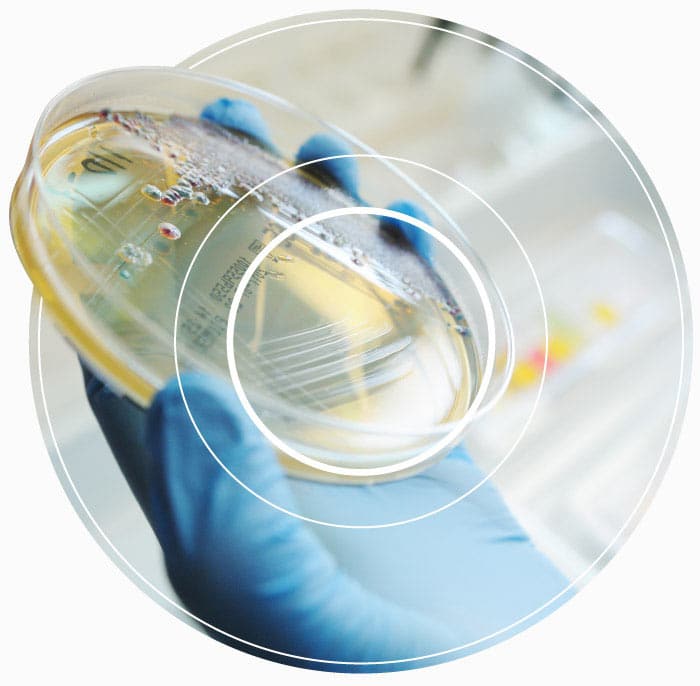

Microbial fuel contamination, known as jet fuel fungus in jet fuel, or diesel bug in diesel, is detected through specially designed fuel tests. Traditionally, these tests are performed off-site, with a delay of up to 10 days to get the results. However, you can perform the procedure on-site with more modern fuel tests such as FUELSTAT®.

Read More >> Diesel Fuel Contamination // Diesel Fuel Contamination Test Kit // Jet Fuel Contamination

FUELSTAT® 15-minute jet fuel test

Easy immunoassay antibody testing that finds all dangerous microbes in aviation fuel.

What happens when microbial contamination is left to grow unchecked?

Microbial contamination, and high levels of microbial biomass (i.e. accumulation of microbial cells), can:

- Reduce mechanical performance

- Stop engines working

- Block and damage filters

- Cause fuel gauges to malfunction

- Eat away at steel and its linings

- Corrode fuel tanks, leading to leaks

For commercial enterprises that rely on these fuels, the effects can be devastating. Costs soar as the company pays to treat the fuel, repair any malfunctioning components, and take assets out of action.

In cases of aircraft fuel contamination, planes can be grounded for repair, costing the company as much as $500k per day.

To avoid the costly consequences of contaminated fuel, regular testing of fuel samples is absolutely essential.

Read More >> Aviation Fuel testing

What fuel tests detect microbial contamination?

CFU Growth Tests

Performed off-site or partially on-site depending on method, taking up to 10 days to get results after incubation.

MRO and FBO repair partners

They use jet fuel test kits to test fuel being taken from an aircraft in a maintenance/safety process called defueling. This helps them to establish that the fuel is free from microbiological contamination before it is stored with general fuel stocks. They will also carry out a jet fuel test whilst undertaking regular maintenance.

Immunoassay antibody testing

Fast, on-site testing with no equipment required

Each of the three tests can directly or indirectly detect microbial contamination, however, some are less practical in certain situations. The most appropriate test will depend on your testing requirements and budget.

FUELSTAT® 15-minute fuel contamination test

Immunoassay antibody testing for all known microbes that are dangerous to fuel.

Fuel contamination tests

01.

IP385 CFU: a traditional off-site fuel contamination check

The IP385 CFU test has been around since the late 19th century and will detect any culturable microbes in a sample. However, the results make it challenging to understand what microbes have grown and whether they will cause problems in fuel systems and tanks.

This method also misses dead or dormant microbes, which could cause problems (dead biomass can still block filters and dormant microbes may become active under given conditions).

Outcomes from the IP385 CFU test are gained in a somewhat old-fashioned way. Technicians will count dots with a pen or compare the density of the colonies against a fuel contamination chart. The amount of microbial contamination is then assessed against established standards from IATA, or against fuel manufacturers’ guidelines.

If a substantial number of microorganism colonies are found, this may lead to a verdict of heavy microbial contamination. This means that owners of the fuel may conduct cleaning and/or apply biocide after the testing.

Another method of CFU testing is called the Thixotropic Gel method a method where the sample can be placed in a bottle supplied by the manufacturer on-site then incubated for a period afterwards.

However, in reality, the verdict may be a false alarm. CFU counts living microbes at the moment of testing, even the ones that aren’t specific to fuel and may have entered the sample during sampling, handling or transportation. And if a misleading result about contamination is given, the cleaning/biocide treatment would have been totally unnecessary.

02.

Is it worthwhile to send fuel samples for off-site testing?

- Transport the fuel samples as hazardous good

- Ship the samples under ice

- Deliver them to their destination within 24 hours

As well as the costs involved, there are additional problems with this. Even under ice, samples may experience changes in temperature during the journey, for example, if the ice melts or the packaging has faults. Microorganisms are dynamic and, if present, they can grow rapidly in warm temperatures, go dormant in more moderate temperatures, or finish their short life cycle in transit.

Any of these changes could mean that the fuel samples may not be representative of the fuel in your tanks. Subsequently, the off-site test may detect dangerous contamination levels where they are not present (if the microbes grow in transit), or fail to detect contamination (if the microbes go dormant or die).

03.

ATP (Adenosine Triphosphate): a fast but highly technical fuel contamination test

However, there are some downsides to ATP:

- Cost. ATP requires laboratory machinery known as a luminometer in order to gain the result. Suppliers or users of fuel who do not conduct many tests, or who are spread out geographically, may struggle to justify the capital outlay.

- Training. ATP fuel testing also requires some skill in conducting the test and is normally conducted by operatives with some scientific experience. These skill sets may not be available in every location, which is an important factor to consider.

- Testing scope. Just like IP385 CFU, ATP is a ‘catch-all’ fuel contamination test. It targets all living cells present in the sample at the time of the test. Even cells that entered the sample during transport/ handling are targeted and will count towards the estimation of the contamination level. This means that misleading results are possible.

04.

Immunoassay antibody testing: a fast, modern alternative method that specifically detects microbes causing fuel problems

The tests are simple to use and learned quickly, even by people with no scientific or laboratory knowledge. They can be conducted on the spot at the tank.

Immunoassay only searches for specific microbes that cause issues in jet and diesel fuel systems. The benefit is that cross-contamination from other (non-dangerous) microbes is almost a non-issue. Immunoassay antibody tests don’t target those microbes, so they’re very unlikely to cause false alarms.

Results are easy to understand, and the users don’t need to make further interpretations. Immunoassay antibody tests tell you:

- What groups of microorganisms are in the sample, be it bacteria, fungi or the specific H. res fungus

- What levels of microbial contamination is present. This is expressed as:-

- Green (Negligible)

- Yellow (Moderate)

- Red (Heavy)

In line with IATA and manufacturers’ manuals, without the need for any further calculation or cross-checking.

FUELSTAT®: the 15-minute immunoassay antibody test for detecting microbial contamination

Why use FUELSTAT® Plus?

- Works anywhere. The tests can be done on-site, no lab needed.

- Fast and easy. FUELSTAT® tests typically take just 15 minutes.

- Only minimal training required. No scientific or laboratory knowledge is needed.

- No extra equipment costs. Everything you need comes in the fuel testing kits.

- Results recorded digitally. Use the FUELSTAT® app for a reliable digital record.

FUELSTAT Plus test is sold in over 130 countries and used by over 400 airlines. It’s 100% compliant with International Standard ASTM D8070.

Learn more about FUELSTAT®

See how FUELSTAT® can save you time and money by testing for fuel contamination early